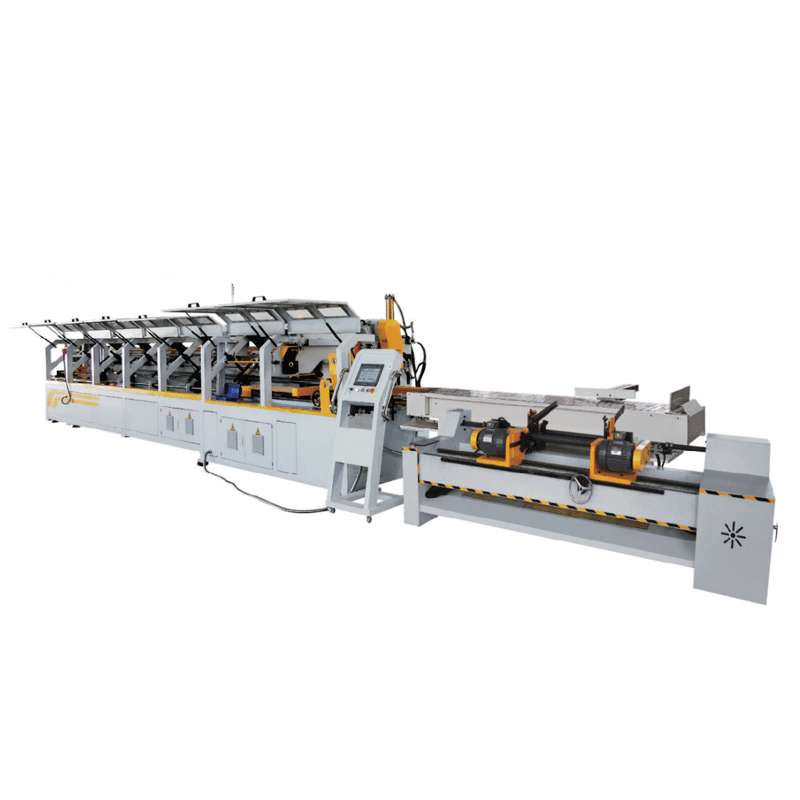

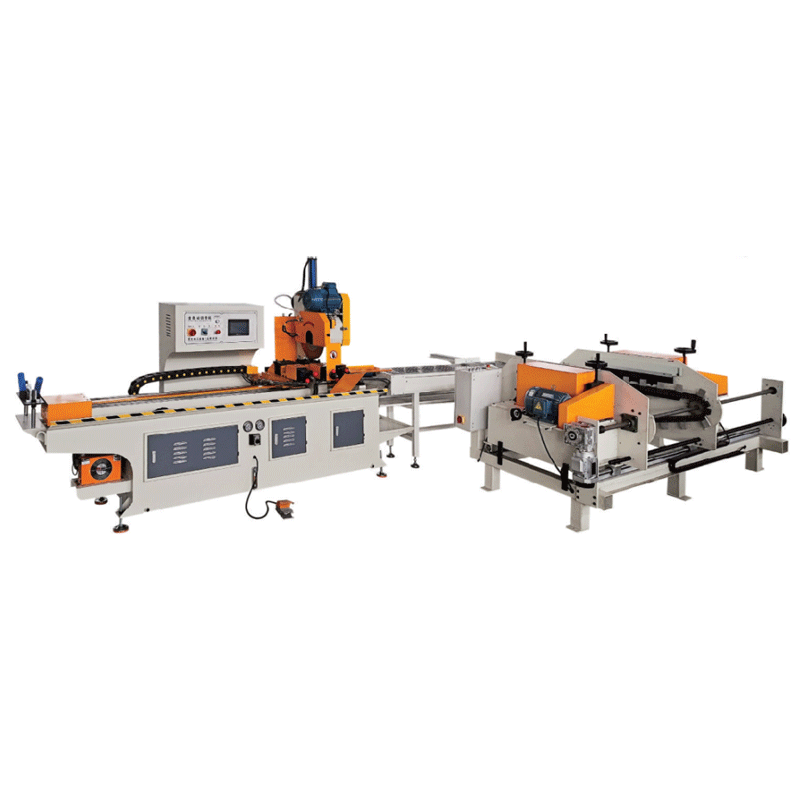

AUTOMATION PIPE CUTTING PRODUCTION LINE

- Theautomaticfeeding and unloading pipe cuting machine adopts advanced CNC numerical control system to realize the unmanned fulldigital production process and modular combination of the pipe cutting production line.Functional device modules are automatic feeding machine,numerical control servo pipe cuting machine,discharging machine,deburing machine,chamfering machine,discharge rack,ultrasonic cleaning machine,the above modules can be selected by

customers according to their own needs

- The production processis self-regulatedand monitored by the numerical control system,the production process is stable and product is accurate,and automatic analysis and consultation and classified production can be realized.

- Variousspecifications,sizesand quantities of sawing can be set at the same time,and the system can automatically analyze and classify production.

- The cutting head is amulti-group gear variable speedchassis,which has more stable performance and energy saving The oil circulation cooling system ensures the reliabity and durabiity of the device and prolongs the service lfe of the device.

- Mechanicalmovementstructure and parts allare CNC self-suficient oil lubrication system,so that the mechanical structure movement can better ensure long-term maintenance-free and ultra-long servicelife.

- Uniquefixturedesign to ensure that the product does not scratch,do not collide,and the delivery process is smooth.

- The touch-type man-machine interfaceis easy to operate,and each module system can be operated independently and can be matched,so the maintenance is simple and convenient.

- Sawdustandantirust coolant is equipped with filtration system,centralized treatment,convenient,clean and tidy

- Itisequippedwith an automatic detection alarm information system,which is convenient for users to troubleshoot.

Details

Be the first to review “AUTOMATION PIPE CUTTING PRODUCTION LINE” Cancel reply

Reviews

There are no reviews yet.